Nasz zakład istnieje od 1970 roku, a od 1986 roku pod nazwą REDONEX (z siedzibą w Blachowni koło Częstochowy) stał się producentem części dla przemysłu motoryzacyjnego do produkcji nadwozi.

Obecnie firma składa się z pięciu prężnie rozwijających się, niezależnych od siebie działów, specjalizujących się m.in. w produkcji wyrobów dla motoryzacji i budownictwa oraz w wytwarzaniu artystycznych artykułów dekoracyjnych.

Nadrzędnym celem naszej firmy jest skuteczne zwiększanie swojego udziału na rynku krajowym i europejskim poprzez podnoszenie efektywności produkcji i jakości wytwarzanych wyrobów. Zatrudniamy doświadczonych pracowników, którzy poprzez udział w szkoleniach, podnoszących ich kwalifikacje stanowią pewne zaplecze kadrowe firm.

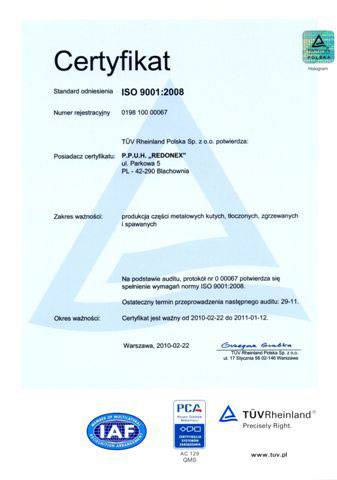

W 2007 roku wdrożyliśmy w firmie System Zarządzania Jakością, uzyskując certyfikat Systemu Zarządzania Jakością oparty na normie ISO 9001:2008. Widząc potrzebę ciągłego podnoszenia jakości swoich wyrobów przeznaczonych dla naszych klientów, przystąpiliśmy do działań mających na celu uzyskanie certyfikatu systemu zarządzania jakością opartego na normie ISO/TS 16949:2002

Cel funkcjonowania i rozwoju przedsiębiorstwa jest ściśle związany z Polityką Systemu Zarządzania Jakością, która jest środkiem do osiągnięcie pełnej satysfakcji klienta. Przez doskonalenie procesów ukierunkowanych na ciągłą poprawę produkowanych wyrobów jest ona naszym zobowiązaniem do realizacji zamówień w sposób rzetelny i kompleksowy, zgodnie z oczekiwaniami kontrahentów i wymaganiami prawnymi. Jest również środkiem do umacniania pozycji na rynku i uzyskiwania wyników finansowych pozwalających na ciągły rozwój naszej firmy.